Delivered site transformations that improved productivity, reduced downtime, and increased service levels across food and FMCG manufacturing.

Led multi-site operations, scaling teams and capabilities while embedding strong governance and performance management.

Turned around underperforming sites, stabilising operations and aligning them to long-term growth and profitability.

Six Sigma Master Black Belt: designed and led CI programmes that delivered sustainable cost reductions and efficiency gains.

Built transformation roadmaps that aligned operational excellence with strategic growth.

Created cultures of continuous improvement, embedding lean and data-driven decision making at all levels.

Full P&L accountability in COO roles, driving both top-line growth and margin expansion.

Led M&A due diligence and post-deal integration, aligning operations and supply chains with strategic objectives.

Delivered multimillion-pound cost-out programmes without compromising service or quality.

Optimised end-to-end supply chains, from forecasting and planning through to warehousing and last-mile distribution.

Delivered logistics transformation projects, reducing costs while improving customer fulfilment and service reliability.

Implemented supply chain resilience strategies to manage volatility and protect margins.

Implemented ERP, WMS, and planning systems to drive visibility and efficiency across operations.

Leveraged data analytics to enable demand forecasting, inventory optimisation, and executive decision making.

Introduced automation and digital tools to modernise legacy operations.

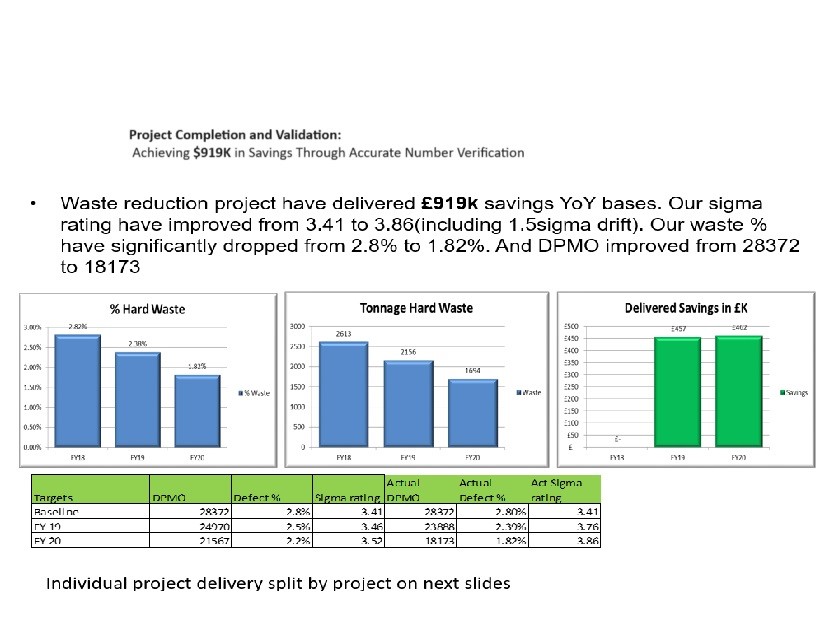

The project has successfully reduced waste from 2,613 tons to 1,694 tons, resulting in a minimum of $919,000 in savings. This achievement comes from the completion and validation of 15 distinct projects by the financial team. Additionally, new projects have been identified and are currently progressing through the pipeline. The project has also contributed to the professional development of the team, with 6 individuals certified as Lean Six Sigma Yellow Belts and 1 as a Black Belt.

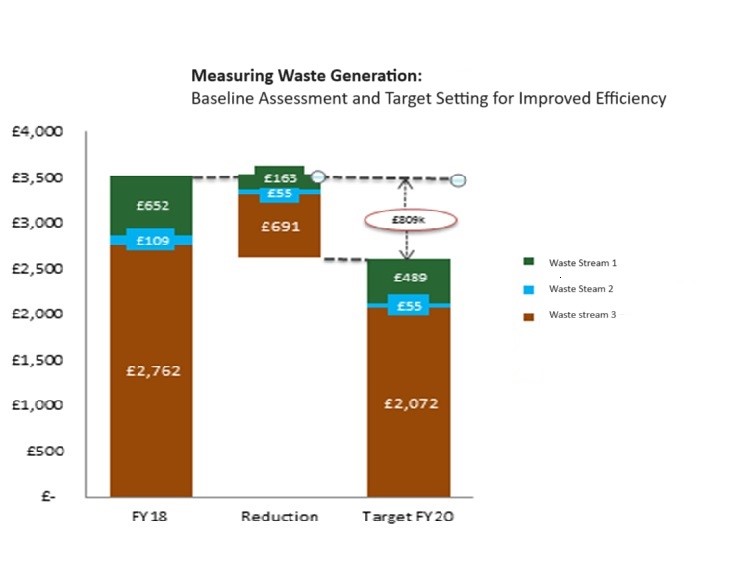

“Evaluating Waste Streams: Measuring Baseline Waste Generation and Target Setting for Improved Efficiency”

Focuses on assessing baseline waste generation and setting targets to enhance waste management efficiency.

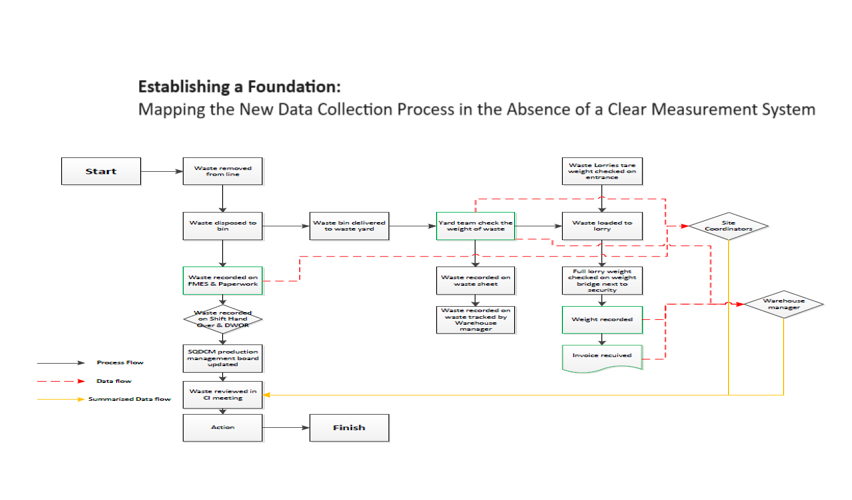

“Designing the Blueprint: Mapping the New Data Collection Process in the Absence of a Clear Measurement System”

Involves creating a new data collection process map where no existing measurement system is in place.

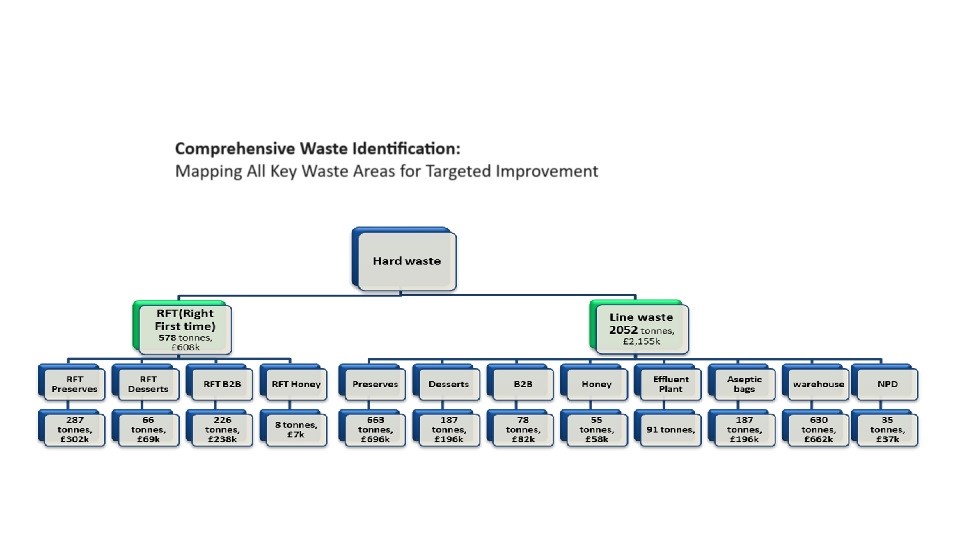

“Comprehensive Waste Mapping: Identifying and Quantifying Opportunities for Improvement”

Addresses the identification and quantification of all waste areas to find opportunities for improvement.

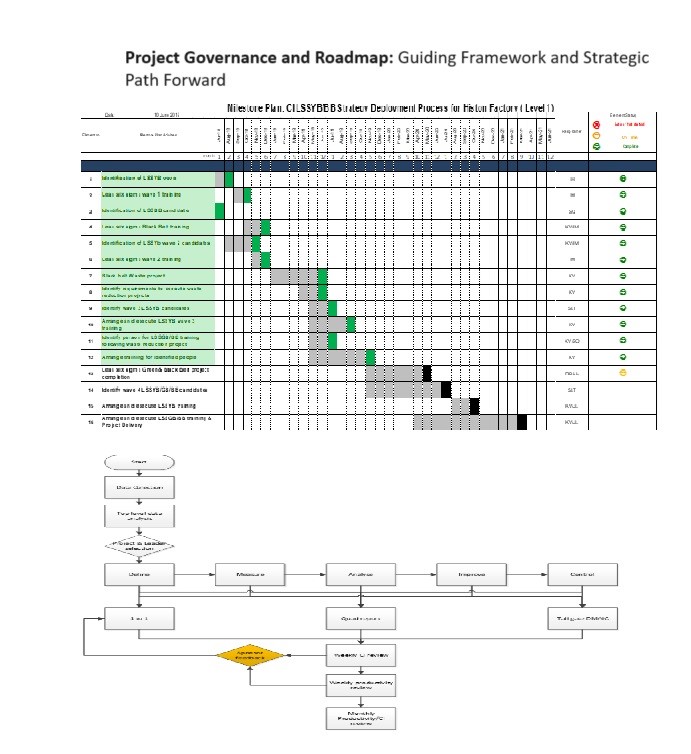

“Project Governance and Roadmap: Guiding Framework and Strategic Path Forward”

Outlines the governance structure and strategic plan for guiding the project’s execution.

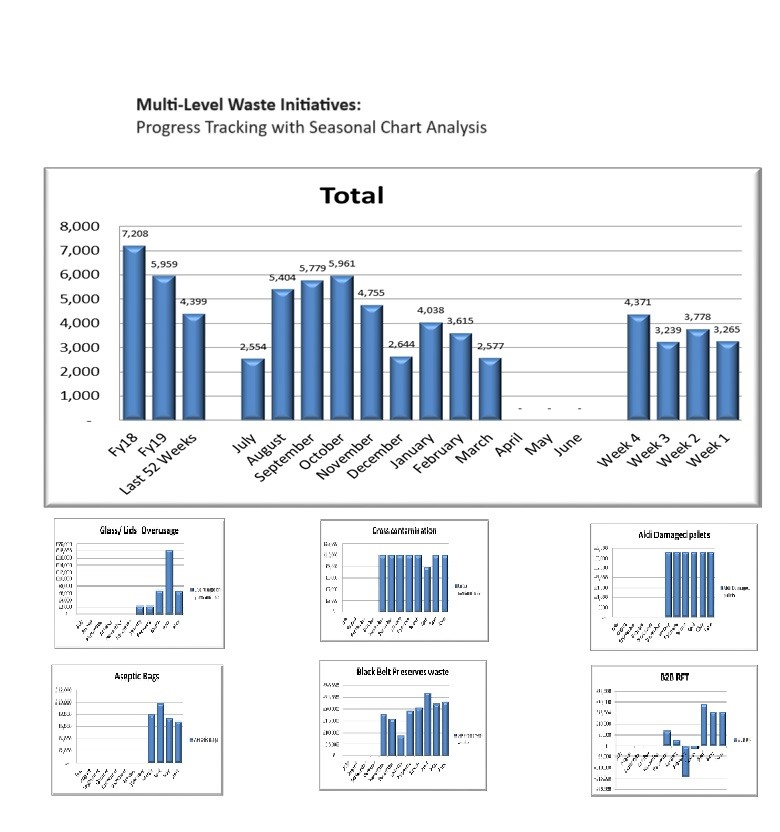

“Multi-Level Waste Initiatives: Progress Tracking with Seasonal Chart Analysis”

Focuses on tracking the progress of waste initiatives at different levels using seasonal charts for detailed analysis.

“Project Completion and Validation: Achieving $919K in Savings Through Accurate Number Verification”

Highlights the successful project completion and validation process, which resulted in $919K in savings through precise number verification.

This group-wide project was designed to significantly reduce supply chain and procurement expenditure across our UK businesses. The initiative involved a collaborative effort from cross-functional teams, including Technical, NPD (New Product Development), Operations, Health & Safety, Engineering, and Finance, to thoroughly analyze over £100 million in expenditure at multiple organizational levels.

Through a series of workshops conducted across all business units, we identified and initiated a pipeline of projects targeting a 10% reduction in costs, yielding substantial financial savings. In addition to this, we identified 156 additional projects that were not included in the initial 10% reduction but present further opportunities for future cost savings.

To ensure the success and sustainability of these initiatives, we implemented robust governance structures and project management practices. This included resource allocation, training team members in Lean Six Sigma methodologies, and enhancing internal capabilities to minimize the need for external resources.

This project underscores our commitment to operational excellence and demonstrates the effectiveness of cross-functional collaboration in achieving significant, sustainable cost reductions.