About Karolis Varnas

Operational transformation shaped across 21+ UK sites — grounded in real experience, real pressure, and real results.

I help owner-led and growing businesses stabilise operations, unlock capacity, and build confident, aligned teams — through a practical, reality-first approach.

A Practical, Reality‑First Approach to Operational Transformation

How I diagnose operations, improve performance, and build capability that lasts

I help owner‑led and growing businesses stabilise operations, improve performance, and unlock capacity across manufacturing, logistics, and supply chain environments. My approach is shaped by hands‑on experience across 21+ UK sites — from high‑care food factories to multi‑temperature distribution and e‑commerce fulfilment.

I always begin with the bigger picture: performance trends, customer impact, demand patterns, and where the numbers signal friction.

But numbers only tell part of the story. To understand what's really driving outcomes, I validate those signals in the operation itself — where flow, behaviours, and constraints become visible in real time. This reality‑first approach ensures improvements are practical, sustainable, and grounded in how your operation actually works.

"Most operational issues are systemic, not individual — and the system always tells the truth."

Culture is central to operational improvement. I look at whether people feel supported, whether skills match expectations, and whether teams are aligned or working in silos. Many performance issues stem from unclear roles, capability gaps, or inconsistent leadership routines — and addressing these is essential for long‑term stability and scale.

From Shop Floor to Boardroom — A Partner Who Understands Your World

Small teams run like speedboats — fast, agile, and responsive, but often reliant on a few key people to keep everything moving. Larger organisations operate more like ocean tankers — slower to turn, but supported by systems, structure, and depth that reduce risk and dependency.

What if you could build a tanker that moves with the agility of a speedboat?

Most growing businesses struggle in the gap between the two. They are no longer small enough to rely on heroics, but not yet structured enough to scale safely. That is where operational pressure builds, decisions get stuck, and leaders feel they must be everywhere at once — a pace that isn't sustainable for the business or the people running it.

My role is to help owner‑led and growing businesses bridge that gap — preserving speed and flexibility, while building the processes, capability, and confidence that remove bottlenecks and reduce risk.

My journey began on the factory line as a line operative. I learned operations from the ground up — mastering each role, solving real problems, and understanding how decisions play out in real time.

I was also extremely lucky. Throughout my career, I had leaders who trusted me with responsibilities far bigger than my age or job title. They put me into situations where I had to grow fast — sometimes faster than felt comfortable — and that exposure shaped me more than any course or framework ever could.

While many people spend years steering one steady, predictable boat, I was thrown into storms across entire fleets — complex, high‑pressure environments where I had to learn fast and make sense of systems far bigger than myself. That intensity shaped the instincts I rely on today.

I've also delivered large‑scale transformations in major organisations such as Greencore and Hain Daniels, and collaborated with leading consultancies including Roland Berger, Alvarez & Marsal, AlixPartners, EFESO, Hansaya Consulting, and S A Partners — often leading high‑stakes initiatives on their most critical projects. Those experiences gave me a front‑row seat to what world‑class operations look like — and how to translate that into practical, scalable solutions for growing businesses.

Why Varnas Consulting

Businesses often struggle to choose between traditional consultants and interim executives. Varnas Consulting sits deliberately between the two — combining hands-on delivery with external objectivity.

Traditional Consultants

- Strong at diagnosis and recommendation

- Limited involvement in execution

- Often disengage before results are embedded

- Low accountability for sustained outcomes

Best when: strategic analysis or high-level design is required.

Interim Executives

- Embedded, hands-on leadership

- Focused on day-to-day delivery and stabilisation

- Limited external objectivity

- Often constrained by internal politics or bandwidth

Best when: a leadership gap needs immediate coverage.

Varnas Consulting

- Executive-level operational leadership

- Structured transformation delivery

- Hands-on execution with external objectivity

- Accountable for measurable commercial outcomes

- Builds internal capability that lasts

Best when: the business needs real change delivered at pace.

Where My Approach Comes From

My approach was shaped by years inside real operations — automated plants, people‑driven lines, and environments where every decision shows up instantly in performance. That experience taught me how systems behave under pressure and how small signals often reveal much bigger truths.

Over time, I developed the ability to spot patterns quickly — the bottlenecks, behaviours, and interactions others often miss — and understand how they connect back to performance, customer impact, and flow.

When I walk an operation, I'm reading the system — flow, constraints, handovers, behaviours, and decision points — and understanding how they interact in real conditions. Tools like timings, process mapping, and structured problem‑solving support this, but the real value is the instinct built from thousands of hours across dozens of environments.

But lasting change doesn't come from me seeing the problem — it comes from helping others see it. My role is to make the important things visible: the patterns, the logic, the causes behind the symptoms. Once teams understand these drivers for themselves, they take ownership, make better decisions, and improvement becomes part of how they think.

The Experiences That Shaped My Way of Working

Long before I knew the terminology, I was already working in a way that focused on systems, not blame. Later, Lean gave me the language to explain what I was seeing and to teach teams how to diagnose problems themselves.

My approach was shaped further by delivering large‑scale transformations alongside consultancies such as Roland Berger, Alvarez & Marsal, AlixPartners, EFESO, Hansaya Consulting, and S A Partners. Each partnership exposed me to different ways of thinking — from structured strategy development to capacity modelling and multi‑site transformation logic.

Working with them taught me how major organisations secure buy‑in, navigate executive‑level tensions, and drive change at scale. But the delivery — the part that actually moves the numbers — always came from applying my own instincts and grounding everything in the real operation.

The same principles have worked everywhere: from small, hands‑on teams to multi‑site, group‑wide transformations. The approach scales because it's built on fundamentals — clarity, flow, ownership, and reality.

I don't push a single methodology. I've seen too many systems — mine, Lean, Toyota, and multiple consulting frameworks — to believe one approach fits every business. Instead, I choose the right tools for the situation, adapting them to your operation so change is practical, sustainable, and owned by your people.

Brands I've Lived and Worked Inside

I've worked across a wide range of food manufacturing, FMCG, and distribution environments — from premium craft suppliers to multi-site, high-volume operations.

Hands-on operational experience across 21+ UK sites within these organisations — from single premium locations to multi-factory national networks.

Tom Hixson of Smithfield

Premium wholesale trading and catering butchery operations

(Led Tom Hixson & Co and A&B Catering Butchers simultaneously — 4 locations)

Hain Celestial (Hain Daniels)

Branded and own-label food manufacturing

(Multi-site national network)

Greencore & Bakkavor

Leading convenience food-to-go and chilled ready meals for major retailers

(Multi-site national operations)

Kerry Foods — Attack a Snack

High-throughput snacking lines

(Dedicated production facilities)

Tulip

High-volume meat processing

(Multi-site operations)

Aligning the Whole Business Around One Reality

Many operational problems come from people working with different assumptions, pressures, and priorities. I help teams build a clear, shared understanding of how the operation really works so decisions become faster and more aligned.

Through structured floor walks, accurate data, and open discussions, we build a clear operational picture that everyone can act on. This removes confusion, reduces friction, and creates a common language across the business.

I coach managers and senior stakeholders to stay connected long-term through simple, practical routines. Leaders learn what to look for, what questions to ask, and how to respond without blame.

We implement visual tools — SQDCM boards, tiered structures, and real-time priorities — so everyone sees the same information. This makes the business far more agile and responsive.

With alignment comes clarity. Teams focus on delivery, managers spend less time firefighting, and hitting milestones builds momentum across the operation.

Fixing Systems, Not Blaming People

Most performance issues come from the system, not the individual. I never blame people — I redesign processes around them and create psychological safety so teams feel secure to speak up.

I spend time on the floor across all shifts and conditions — day vs. night, peak vs. quiet — revealing realities you can't get from reports. This ensures recommendations are practical and owned by the people delivering them.

Toyota's Andon Cord system is a perfect example: any worker can stop the line to flag an issue, without blame. The result? Fewer defects, faster problem‑solving, and a culture where everyone contributes to excellence.

This no‑blame mindset has been central to the transformations I've led — reducing waste by up to 39%, cutting complaints 5.5×, and freeing teams from unnecessary friction so they can focus on what matters.

What This Means for Your Business

The real shifts — like 5.5× fewer complaints, absenteeism from 7.2% to 2.2%, 39% waste reduction, reclaiming 38 hours per person per week, and £10M+ savings — happened when teams started seeing the operation clearly and working with confidence.

I focus on what truly moves the needle — cutting out flashy initiatives that deliver little, and prioritising the changes that create real impact.

This combination of deep shop‑floor experience, practical problem‑solving, and exposure to strategic thinking is rare. It allows me to shape a tailored operational model that fits your management style, your team's capabilities, and your future vision.

We build it together — grounded in reality, adaptable to your business, and designed to last long after I'm gone.

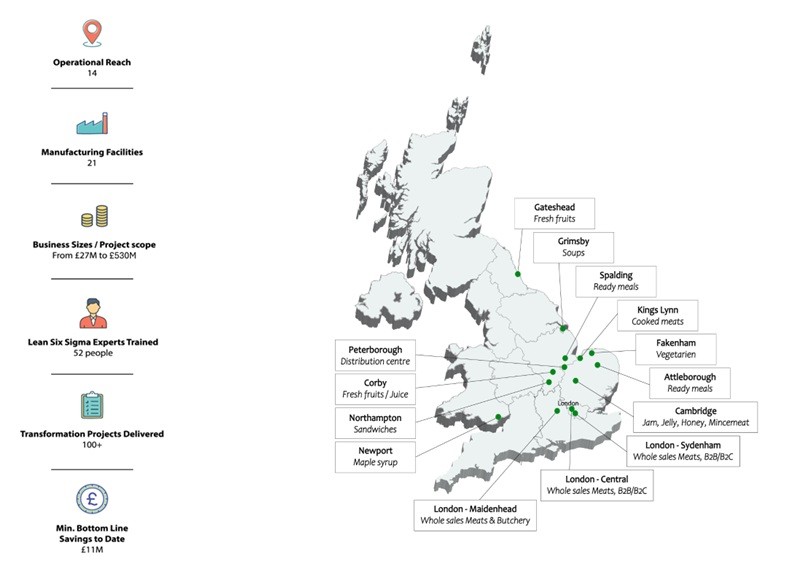

Proven Experience Across 21+ UK Sites

I've worked across more than 21 sites throughout the UK — from high‑care chilled factories to multi‑temperature distribution centres and complex ready‑meal operations. This breadth of exposure helps me recognise patterns quickly and understand how different environments behave under pressure.

This includes exposure across London, Northamptonshire, Cambridgeshire, Lincolnshire, Yorkshire, the Midlands, and the North West — each with its own operational challenges, labour dynamics, customer pressures, and cultural differences.

Let's Talk About Your Operation

Whether you're stabilising performance, unlocking capacity, or preparing for growth, I can help you understand what's really happening in your operation — and what to do next.

No pressure, no obligation — just a practical conversation about your challenges and what's possible.

Book a call